Beautiful Les Paul Standard tops, from left to right: 9 0627, 9 1854, 9 0823, 9 0629

Beautiful Les Paul Standard tops, from left to right: 9 0627, 9 1854, 9 0823, 9 0629

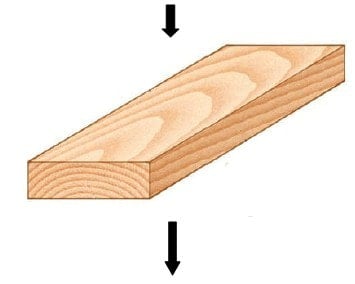

All Les Paul Standards manufactured between 1958 and 1960, often nicknamed "Burst" by guitarists, had a top consisting of two side by side maple boards. The wood used was usually acer saccharum, also known as hard or rock maple, but sometimes Gibson also used acer saccharinum, known as silver maple, or acer rubrum, known as red rum maple.

Ted McCarty and John Huis, Gibson factory manager, picked maple trees in a forest in East Lansing, Michigan, and had them cut in a sawmill owned by the Forestry Department of the Michigan State University.

The body (top excluded, of course) was in "old growth" Honduran mahogany, obtained from trees that were hundreds of years old.

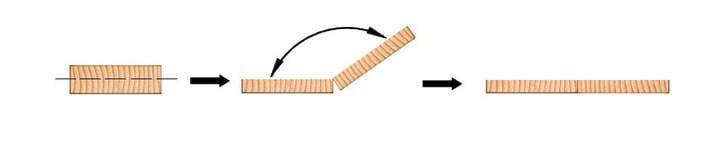

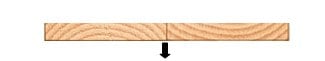

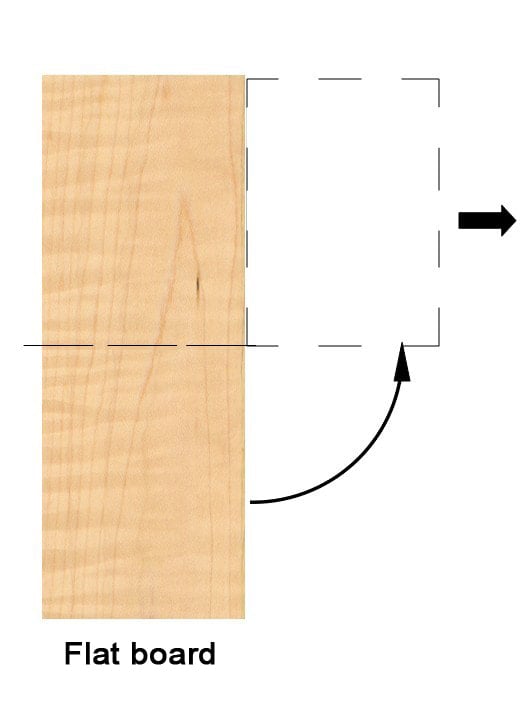

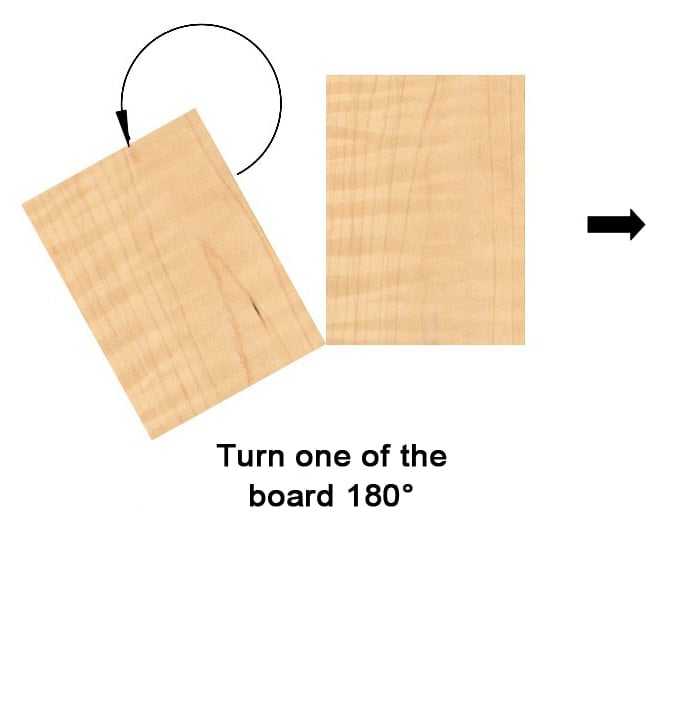

Since the top of the Les Paul was in a see-through Sunburst finish, it was important to make it as elegant as possible. Book-matching was used to create unique tops, just like fingerprints, and to maximize the beauty of the wood. It was done by cutting the maple board in half and opening it like a book, in order to obtain two symmetrical boards creating pleasing visual effects.

Ted McCarty and John Huis, Gibson factory manager, picked maple trees in a forest in East Lansing, Michigan, and had them cut in a sawmill owned by the Forestry Department of the Michigan State University.

The body (top excluded, of course) was in "old growth" Honduran mahogany, obtained from trees that were hundreds of years old.

Since the top of the Les Paul was in a see-through Sunburst finish, it was important to make it as elegant as possible. Book-matching was used to create unique tops, just like fingerprints, and to maximize the beauty of the wood. It was done by cutting the maple board in half and opening it like a book, in order to obtain two symmetrical boards creating pleasing visual effects.

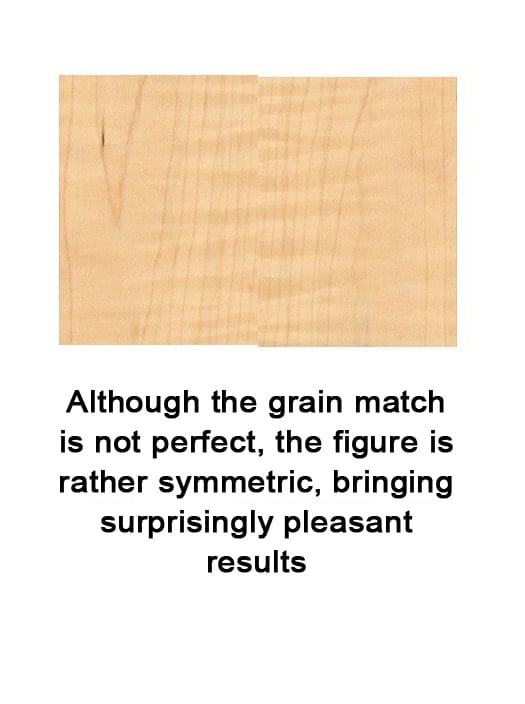

On acoustic instruments, such as violins or acoustic guitars, this technique not only highlights the aspect of the wood grain, but, also serves to give structural resistance to the body; for this reason, only quarter-sawn boards can be used, the only ones capable of providing the necessary stability as well as creating beautiful patterns.

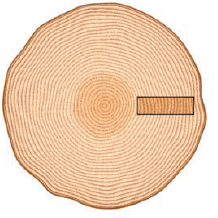

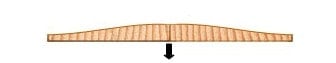

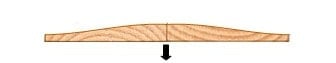

Quarter-sawn, rift-sawn and flat-sawn

Quarter-sawn, rift-sawn and flat-sawn

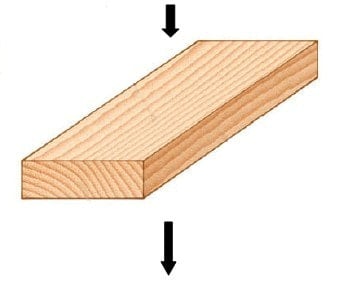

Since the top of the Les Paul Standard was not carved out from the inside and was joined to a strong mahogany body, the structural strength and stability were already assured. Therefore flat-sawn and rift-sawn boards, discarded in acoustic instruments manufacturing, could be used as well, reducing unnecessary costs. This was particularly useful for Gibson, which needed at least 5/4 lumber. Larger mills would usually cut the board to the "standard" thickness of 4/4. Therefore, Gibson was forced to obtain 5/4 boards from smaller lumber mills, significantly reducing the number of boards available with an increase in production costs.

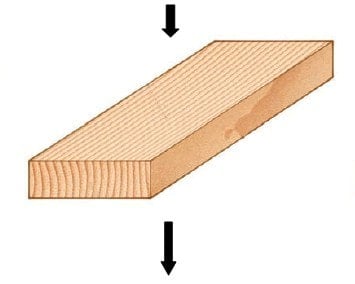

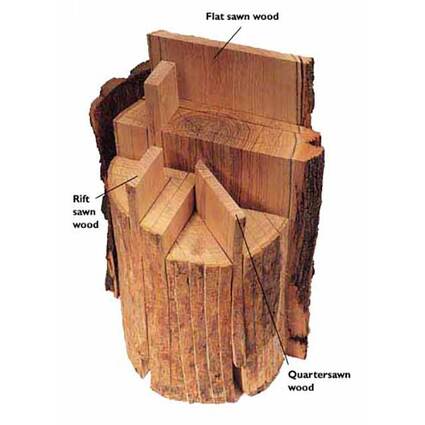

According to the cut and the plan, the boards could have different grain and be more or less figured.

It's now important to understand the meaning of grain and figure.

According to the cut and the plan, the boards could have different grain and be more or less figured.

It's now important to understand the meaning of grain and figure.

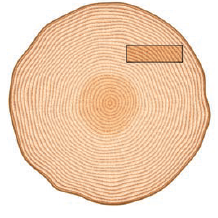

The grain is a two-dimensional pattern that appears on the surface of the board, direct consequences of the annual rings. It is created as the tree grows: the darker rings form during the winter, when tree growth is slower. Depending on the angle of the cut you can have different patterns.

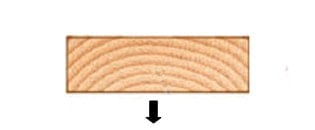

- In quarter-sawn boards growth rings run parallel to the board edges and run at an angle between 60° to 90° to the face of the board. Straight parallel lines appear on the surface; on the side, rings intercept the edges, leaving irregular shapes.

- In flat-sawn boards growth rings intercept the surface, leaving a cloud-like grain pattern on the top surface and a rainbow-like grain pattern on the front face. On the side, annual rings may run "uphill" or "downhill", depending on the cut.

- Rift-sawn boards are between quarter-sawn and flat-sawn boards. Furthermore, the board in one point can be more similar to a quarter cut, on the opposite side it can be more "flat". Growth rings run at an angle between 30° and 60° to the face of the board.

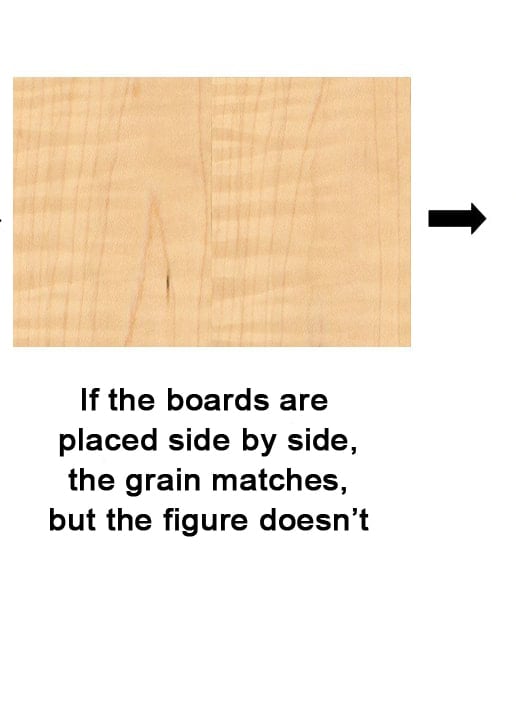

The figure is a completely different phenomenon, caused by a drastic change in fiber orientation and its density. It usually interlocks with the grain. The light is reflected from a certain pattern of the top surface, creating optical illusions to the human eye which makes Les Paul tops particularly attractive. Ribbon curl, tiger-striped, curly, pin-striped, fiddleback and flamed are several different three-dimensional patterns that appear on the surface of only a few boards. Usually particularly flamed tops were reserved for other models, more important to Gibson, such as the Super 400 and the L-5, but it was possible to find them on a few Les Paul Standards. Probably Gibson at first paid less attention to the aesthetic aspect of the Les Paul top, so there is a higher percentage of figured tops in '59 compared to '58, but given that their use depended on the availability in stock, a clear distinction of their use based on years, cannot be made. The truth is that each year most of the Les Paul Standard tops were plain or with moderate figures.

There is a close relationship between figure and grain. Generally, figure is strongest on quarter-sawn boards and may be not so prominent on flat ones. But the figure is often not very reflective on quarter-sawn boards and may not have enough "movement" as the viewing angle changes.

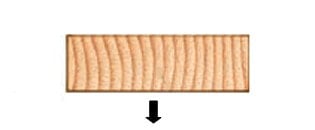

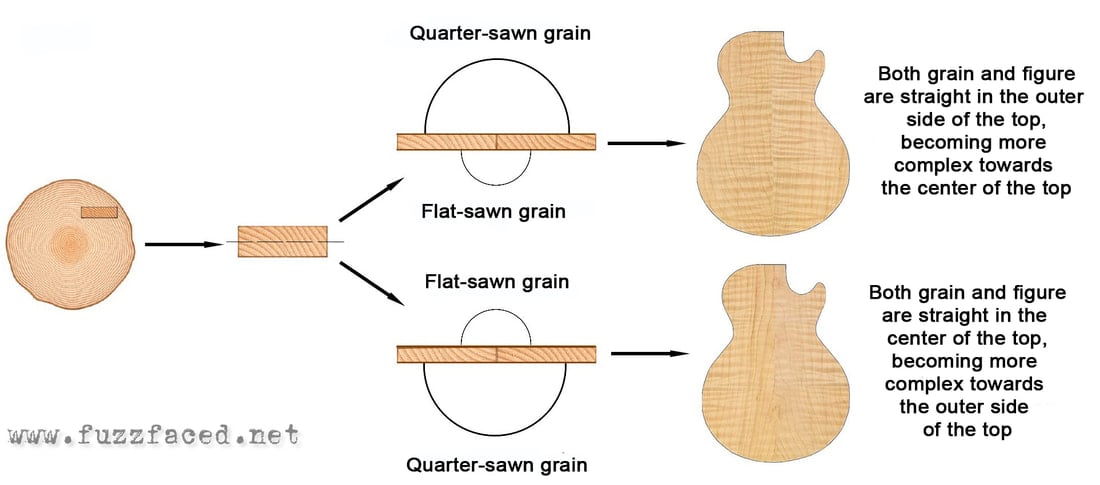

Les Paul tops consisted of two symmetrical side by side boards. '50s Les Paul tops were 1/2" in the center part, while the thinnest outer edge was 9/64". Therefore, after carving, a considerable amount of wood was discarded. This did not change the pattern on the new carved surface of the quarter-sawn boards and both figure and grain remained straight. But two- and three-dimensional patterns on rift and flat boards, which represented the majority of the Les Paul tops, varied considerably, losing the symmetry given by the book-matching. After carving, most flat-sawn boards were devoid of three-dimensionality, but some rift-sawn boards still had beautiful figures.

|

Comparison between quarter, flat and rift sawn, and related top patterns

|

Rift sawn boards usually had a quarter-tending edge and a flat-side one, so they could be book-matched with the flat edge in the center or, as in the case of most Les Paul Standard guitars, they could be joined with a quarter edge in the center.

After cutting the lumber in half to get a book-match, it was possible that one out of the two sliced boards was discarded for various reasons, such as cosmetic imperfections. The remaining board was saved and matched with the same lumber for color, figure and grain.

When a book-matching was not possible, Gibson used to cut the lumber at its body length, making a side-by-side figure matching. The surface exposed was the one closest to the bark side of the tree, which usually was more figured. This is called flitch-matching.

If this was not possible, Gibson matched the boards by color only. As the Sunburst finish was a see-through finish, the color-matching was important. So the factory would have opted to match the boards from the same lumber although they were not adjacent, rather than risking the matching from different piece of lumber.

When a book-matching was not possible, Gibson used to cut the lumber at its body length, making a side-by-side figure matching. The surface exposed was the one closest to the bark side of the tree, which usually was more figured. This is called flitch-matching.

If this was not possible, Gibson matched the boards by color only. As the Sunburst finish was a see-through finish, the color-matching was important. So the factory would have opted to match the boards from the same lumber although they were not adjacent, rather than risking the matching from different piece of lumber.