NECK JOINT SYSTEMS

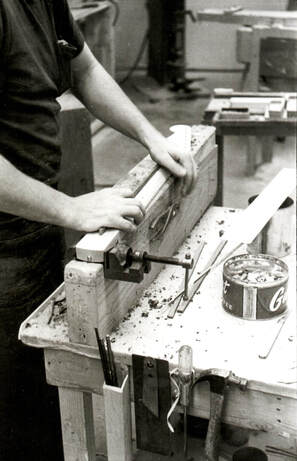

There are three ways to attach a neck to a guitar: neck-through (or through-body), set-neck and bolt-on. Fender instruments have almost always used a bolt-on neck attachment design, the most convenient to adjust, repair or replace. Neck is inserted in a pre-routed pocket in the body and joined using four or sometimes three screws. A rectangular metal plate (neck plate) is used to secure the joint and re-distribute the screw pressure. It was produced with a 16 gauge cold rolled steel to which boron was added for surface hardening. Neck plates used on early prototypes were smaller, because the tooling for the final plate was invoiced on April 26, 1950.

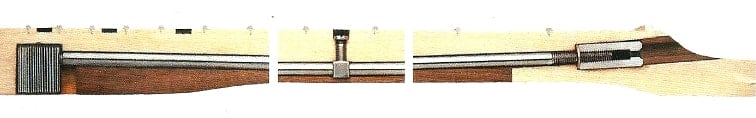

The Truss rod

|

The truss rod is a rod inserted into the neck to reinforce and to help keep it straight and true. Almost all Telecaster and Esquire necks are equipped with a truss rod, but they do not share the same truss-rod installation and adjustment system.

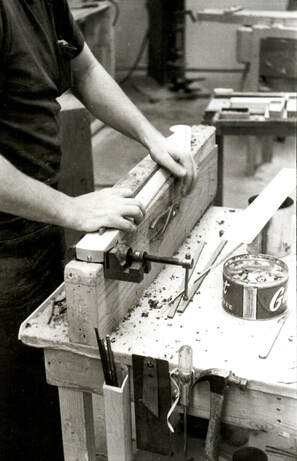

The very first Esquires and Dual Pickup Esquires, all prototypes, sample and pre-production guitars, were deprived of any reinforcing truss-rod. According to Nacho Baños they were no more than twenty guitars made without the truss rod. They can primarily be identified by the lack of truss-rod bolt at the heel, as well as the absence of contrasting stripe on the back. The first production Esquire's and Broadcaster's necks were fitted with a truss rod inserted from the rear via a channel routed in the back spine, subsequently filled with a strip of walnut. The characteristic look that this gave the neck of Fender guitars earned it the nickname skunk stripe. This also explains why these necks had a walnut plug above the nut (to fill the anchoring point of the rod). |

|

Thanks to the truss rod it was possible to adjust the curvature of the neck by a bolt (slothead until early '51, Phillips head thereafter) located in the neck heel, whilst neck angle adjustment could only be achieved by inserting little shims in the neck pocket.

The dimensions of the truss rod and its anchor nut have varied over time. Generally speaking, truss rods made until ’59 was longer than that of the guitars built in the following years. Fender truss rod wasn't made of stainless steel, but of zinc plated steel, and at first it wasn't wrapped in the plastic tube, which was added in 1966 when CBS re-designed the truss rod with a larger section. |

With the advent of a separate rosewood fretboard the truss-rod installation was modified, because it was easier to drill the rod channel in the neck prior to glueing the fretboard. This explains why rosewood-capped (and maple-capped) necks were devoid of the skunk stripe and of the walnut plug.

In early 1969, the original one-piece fretted maple neck was reinstated as an option in lieu of the maple cap board on Telecaster guitars. By then, Fender would have had to deal with two methods of installation of the truss rod, from the front and from the rear. In order to optimize production, only the installation from the rear was retained, and this is why rosewood-capped necks made after Spring 1969 usually featured the skunk stripe and the walnut plug above the nut.

In early 1969, the original one-piece fretted maple neck was reinstated as an option in lieu of the maple cap board on Telecaster guitars. By then, Fender would have had to deal with two methods of installation of the truss rod, from the front and from the rear. In order to optimize production, only the installation from the rear was retained, and this is why rosewood-capped necks made after Spring 1969 usually featured the skunk stripe and the walnut plug above the nut.

Bullet truss rod

|

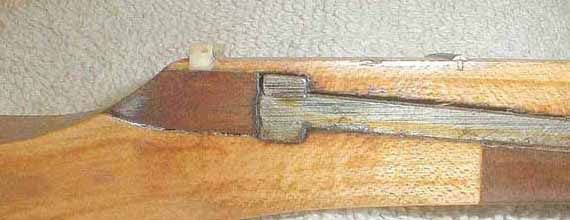

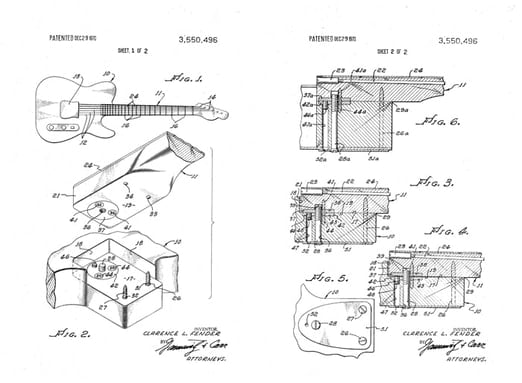

While Leo Fender worked as a consultant for the CBS, he, with the help of Freddie Tavares, came up with a new invention: the tiltable guitar neck incorporating thrust absorbing pivot and locking elements, also known as tilt-neck or micro tilt.

This system was primarily aimed at upper range models and this may explain why it was never fitted to the regular Telecaster, but it became a standard trim on the other Telecaster variants since 1973: the Custom, the Thinline (the second version) and the Deluxe. |

Thanks to the micro tilt the neck angle could be adjusted via a smaller wrench inserted into the lower hole below the screw of a new 3-bolt neck plate (on which the huge Fender “F” and the serial number were stamped). At the same time the truss-rod could be adjusted via a wrench inserted into a metal bullet located above the nut, without disassembling the neck, hence the name bullet truss rod.

The metal disk at the base of the neck was initially housed in a route which surrounded it perfectly. Since ca. 1976, the route was lengthened to reach the end of the neck.

Despite these changes, the truss-rod was still inserted from the rear and this explains the presence of the stripe.

The metal disk at the base of the neck was initially housed in a route which surrounded it perfectly. Since ca. 1976, the route was lengthened to reach the end of the neck.

Despite these changes, the truss-rod was still inserted from the rear and this explains the presence of the stripe.

BIFLEX TRUSS ROD

In early 1983, Fender introduced the very new BiFlex truss rod, which could be adjusted in both directions (concave and convex), via a bolt buried in a small well above the nut. It was first fitted to the 1983 Elite and Standard models. At the same time the micro-tilt was re-introduced, but this time with a 4-bolt neck plate.