FENDER JAPAN

|

In the early '80s a new problem that Fender had to deal with emerged: the rise of the made in Japan guitars, caused by dollar increase against yen and by the quality of the instruments realized in Japan, which made those Americans uncompetitive. These guitars very often literally copied Stratocasters and at the same time they cost less. Since it was difficult to protect Fender design from foreign competition, in 1982 Bill Schultz and Roger Balmer (Fender’s then head of marketing and sales) decided to produce authentic Fender Stratocasters in Japan, in order to compete with the non-original copies. “Not only did we have to get the image of Fender back up again, and get the quality standard built up to make that happen, but we had to stop this plethora of [Japanese] copies,” Dan Smith said. “A lot of arrogant companies, like Tokai, a lot of these companies basically told Bill Schultz and I that they were gonna bury us, that they were gonna be Fender, that whether we liked it or not they were gonna take over the marketplace”.

|

After a meeting with Mr. Kojima from Kanda Shokai and Mike Yamano from Yamano Music, the Fender Japan co. Ltd. was officially announced at the Grand Palace Hotel, Kudanshita, Tokyo, on 11 March 1982. The design and components of the Stratocasters would be pertinent to Fender/CBS and the distribution on the Japanese market would be managed by Kanda Shokai only, while Yamano Music, which invested money in Fender Japan, would deal with the importation into Japan of the instruments produced in the U.S.A.. Kanda Shokai suggested Tokai as one possible factory, but the leaders of Fender USA hated Tokai, they did not trust them at all. So the guitars would be realized by FujiGen Gakki, in Matsumoto, about 200 km north of Tokyo, which was known for its production of the Ibanez and Antoria, and because it manufactured the Greco for Kanda.

For a time, most Fender guitars were made - ironically but strategically - in the factories of its Japanese competitors, the intent being to have Fender-branded instruments beat those competitors’ copy guitars on their own turf, in turn forcing them to raise the retail prices of guitars sold in the USA.

In addition to making guitars for export to the United States and Europe, Fujigen made instruments intended for the Japanese domestic market only. In fact, the instruments Fender Japan offered at home often differed from that available in the Western market, because Fender Japan was free to determine which models to produce and sell to meet the particular demands of Japanese customers.

For a time, most Fender guitars were made - ironically but strategically - in the factories of its Japanese competitors, the intent being to have Fender-branded instruments beat those competitors’ copy guitars on their own turf, in turn forcing them to raise the retail prices of guitars sold in the USA.

In addition to making guitars for export to the United States and Europe, Fujigen made instruments intended for the Japanese domestic market only. In fact, the instruments Fender Japan offered at home often differed from that available in the Western market, because Fender Japan was free to determine which models to produce and sell to meet the particular demands of Japanese customers.

|

The birth of Fender Japan was a huge success for the FMIC. It was a blow to all copies made in Japan. Also Tokai, which produced excellent replicas of the Fenders, suffered from the new MIJ guitars, as Paul Colbert, the first journalist to review the new instruments, reported: “Tokai are as detailed in their replicas but, psychological or not, having that Fender logo at the top of the headstock puts heritage in your hands, even if given an Eastern interpretation”.

The first advertisement of the guitars made in Japan recited: "An international team of guitar designers and craftsman gave these new Squier guitars the same light touch and brilliant tone that made the originals the world's most sought-after electric guitars"; no mention of where the guitars were built was given. |

This led many people to think that American workers didn’t take the news well due to old dislikes that went back to the Second World War. But at the Fullerton factory there was no racial hate towards Japanese. Almost 80 percent of the 1000 workers were Latino, not white, and they had absolutely no racial problems with Japanese. There were, of course, some people who thought the Japanese project would make them lose their jobs, but it wasn’t racial hatred.

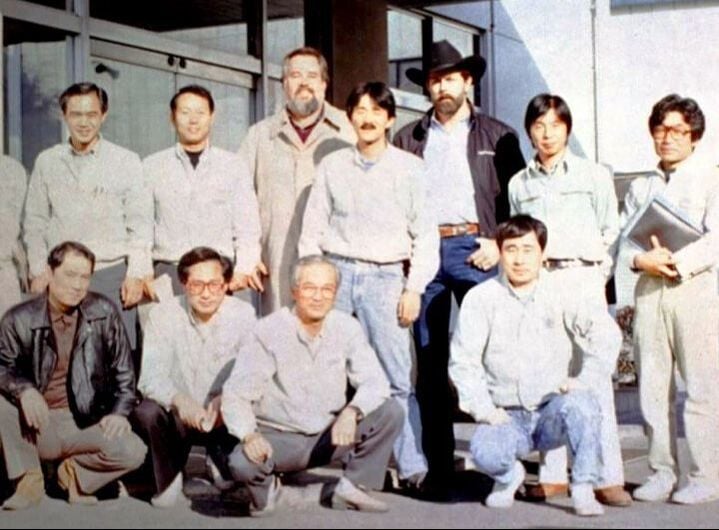

The Japanese Custom Edition Team

In the second half of '80s Makoto "Nick" Sugimoto established a small Custom Edition Team, a sort of Japanese Custom Shop. He is a luthier who had worked for twenty-three years in R&D, custom guitar building and engineering at Fujigen factory. His designs defined Fujigen’s manufacturing for all its customers, including Ibanez, Greco, Epiphone, Yamaha, and, obviously, Fender. He also made the first sample Fujigen sent to Fender headquarters in the USA to show them they had the skill to manufacture Fender guitars in Japan - so, the first sample was not a Greco, as often reported. Makoto left Fujigen in 2001 and in 2002 started manufacturing guitars and basses with his uncle as the original brand Sugi Guitars.

The Custom Edition Team consisted of highly skilled craftsmen; they studied and analyzed Fender guitars and basses a lot, had active relations with Fender USA, used only selected materials and took special orders from guitarists and bassists.

The Custom Edition Team consisted of highly skilled craftsmen; they studied and analyzed Fender guitars and basses a lot, had active relations with Fender USA, used only selected materials and took special orders from guitarists and bassists.

MADE IN JAPAN VS CRAFTED IN JAPAN

In the second half of the 1990s, Sam Sekihara, Managing Director of Fender Japan, approached Fujigen with the idea to change the "Made in Japan" decal with "Crafted in Japan" with the aim of giving a little boost to the image and setting their instruments apart from other Japanese instruments.

At that time, Fender was increasing their orders to Fujigen and delays were starting to happen. The Fujigen Vice President, Mr. Ace, suggested bringing Dyna Gakki (Chino, Nagano prefecture), former Greco’s manufacturer, into the picture. This happened virtually at the same time as the Fender Japan idea to change the Made in Japan decal. Not by plan or design, just by chance. For a while both Fujigen and Dyna produced the very first Crafted in Japan Fender guitars together.

Then Fujigen made the decision to leave the relationship with Fender and the production was gradually shifted to Dyna. The last Fujigen Fender instruments were made in 1997.

At first Dyna couldn’t immediately make 5000 instruments a month like Fujigen, so Fender USA agreed to let Tokai make a very limited number of instruments, only for sale in Japan. As soon as Dyna could match Fujigen monthly quantity, Tokai stopped all work with Fender Japan. Therefore, Tokai was only involved for a few months.

It’s important to bear in mind that Fujigen, like all Japanese manufacturers, relied on a network of subcontractors to make guitars. They were not other large factories. Usually, a subcontractor was a one-man company, but there were a few exceptions, like Atlansia, which made some necks for Fujigen for a while until they were fired because their building techniques were not approved by Fender and caused truss rod problems.

Subcontractors made bodies, necks, fingerboards, pickguards, and wiring, sanded and painted bodies, and assembled guitars. But they didn’t do jobs Fujigen couldn’t do. Usually, subcontractors were involved when they could do a cheaper job or when Fujigen workers were already too busy, thus helping the production move more smoothly.

At that time, Fender was increasing their orders to Fujigen and delays were starting to happen. The Fujigen Vice President, Mr. Ace, suggested bringing Dyna Gakki (Chino, Nagano prefecture), former Greco’s manufacturer, into the picture. This happened virtually at the same time as the Fender Japan idea to change the Made in Japan decal. Not by plan or design, just by chance. For a while both Fujigen and Dyna produced the very first Crafted in Japan Fender guitars together.

Then Fujigen made the decision to leave the relationship with Fender and the production was gradually shifted to Dyna. The last Fujigen Fender instruments were made in 1997.

At first Dyna couldn’t immediately make 5000 instruments a month like Fujigen, so Fender USA agreed to let Tokai make a very limited number of instruments, only for sale in Japan. As soon as Dyna could match Fujigen monthly quantity, Tokai stopped all work with Fender Japan. Therefore, Tokai was only involved for a few months.

It’s important to bear in mind that Fujigen, like all Japanese manufacturers, relied on a network of subcontractors to make guitars. They were not other large factories. Usually, a subcontractor was a one-man company, but there were a few exceptions, like Atlansia, which made some necks for Fujigen for a while until they were fired because their building techniques were not approved by Fender and caused truss rod problems.

Subcontractors made bodies, necks, fingerboards, pickguards, and wiring, sanded and painted bodies, and assembled guitars. But they didn’t do jobs Fujigen couldn’t do. Usually, subcontractors were involved when they could do a cheaper job or when Fujigen workers were already too busy, thus helping the production move more smoothly.

THE FMC jAPAN

FMIC made many changes to the original 1982 Fender-Japan agreement and other joint-ventures, as K.K. Fender Promotion (2000) and Dyna Boeky (2005) were born. Kanda Shokai and Yamano remained Fender's Japanese distributors, each handling different sections of the product range, as mentioned in a Fender's prospectus from their abandoned IPO filed on March 8, 2012: “Following the termination of a joint venture in Japan with two of our greater than 5% stockholders and their affiliates, Kanda Shokai Co., Ltd. and Yamano Music Co., Ltd., we entered into distribution agreements with each of these entities”.

New agreements with these distributors would terminate on December 31, 2012, but they would be renewed automatically for successive three-year terms “if Kanda Shokai meets certain minimum purchase thresholds” and “unless either we [FMIC] or Yamano fails to comply with certain specified conditions”. But conditions weren’t met and, on April 1, 2015, Fender took direct control of the distribution of the instruments manufactured in Japan and, at the same time, the Made in Japan Exclusive Series was presented.

In 2017 the master builder Chris Fleming was invited in Japan to monitor the production of the new Made in Japan Traditional Series born on September 13, 2017 to commemorate the thirty-five years of Fender Japan.

New agreements with these distributors would terminate on December 31, 2012, but they would be renewed automatically for successive three-year terms “if Kanda Shokai meets certain minimum purchase thresholds” and “unless either we [FMIC] or Yamano fails to comply with certain specified conditions”. But conditions weren’t met and, on April 1, 2015, Fender took direct control of the distribution of the instruments manufactured in Japan and, at the same time, the Made in Japan Exclusive Series was presented.

In 2017 the master builder Chris Fleming was invited in Japan to monitor the production of the new Made in Japan Traditional Series born on September 13, 2017 to commemorate the thirty-five years of Fender Japan.

Final notes

There’s a lot of confusion around Japanese guitars: great instruments for some, too overrated for others. The truth is Fender Japan made a lot of instruments, and expensive high-quality models, built by skilled luthiers, were joined by low-budget guitars.

Guitars made in Japan had supported Fender in the first difficult years of post-CBS when the American factory wasn’t still able to meet the needs of the world market, but what happened next? Prices of Japanese electric guitars were going up because manufacturers in Japan proved they could make great instruments, but the market was too competitive to tolerate that and they began to lose market share. At the same time, Mexican Fender guitars, which had taken over the territory Fender Japan had formerly occupied, seemed not as good as the Japanese instruments.

Guitars made in Japan had supported Fender in the first difficult years of post-CBS when the American factory wasn’t still able to meet the needs of the world market, but what happened next? Prices of Japanese electric guitars were going up because manufacturers in Japan proved they could make great instruments, but the market was too competitive to tolerate that and they began to lose market share. At the same time, Mexican Fender guitars, which had taken over the territory Fender Japan had formerly occupied, seemed not as good as the Japanese instruments.

Antonio Calvosa

Very special thanks to Scott Zimmerman

Very special thanks to Scott Zimmerman

CHAPTERS:

- JV and SQ Stratocasters

- The end of JV Strats: New Series Explained

- Standard Stratocasters

- Collectables and Hot Rodded Reissue Series

- Foto Flame

- The ExTrad Series

- Superstrats: Contemporary, HM, Boxer and Pro Feel Stratocasters

- Paisley and Blue Flower

- Ventures, Hellecasters and other signatures

- Silver Series, Squier Series, Wayne's World

- XII-String Stratocasters

- Aerodyne Stratocasters

- Domestic strats since 2015

Production steps in Dyna Gakki factory (Courtesy of Ikebe)